Single gas monitors, although more limited in scope compared to multi-gas detectors, serve specific purposes in various trades and industries. Here's why people use single gas monitors:

1. Specific Hazard Monitoring:

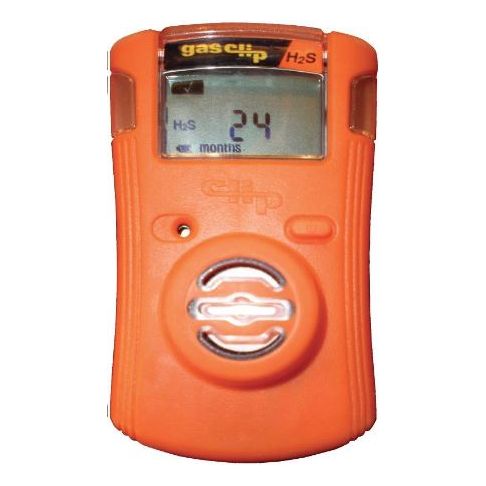

- Focused Detection: Single gas monitors are designed to detect and monitor the concentration of a specific gas, such as carbon monoxide (CO), hydrogen sulfide (H2S), oxygen (O2), or combustible gases like methane (CH4).

- Tailored Solutions: Different industries face unique gas hazards. Single gas monitors allow users to choose the appropriate monitor tailored to the specific gases present in their work environment.

2. Simplified Operation:

- Ease of Use: Single gas monitors are often simpler to operate and maintain compared to multi-gas detectors, making them ideal for users who require straightforward gas monitoring solutions.

- Less Training Required: With a single gas monitor, users only need to learn how to operate and interpret data for one specific gas, reducing the training time and complexity.

3. Cost-Effectiveness:

- Lower Initial Investment: Single gas monitors typically have a lower upfront cost compared to multi-gas detectors, making them an attractive option for users with budget constraints or specific gas monitoring needs.

- Maintenance Costs: Since they have fewer components and sensors, maintenance and calibration of single gas monitors may be more cost-effective over time compared to multi-gas detectors.

4. Specialty Applications:

- High Sensitivity: In some cases, single gas monitors offer higher sensitivity and accuracy for detecting specific gases compared to multi-gas detectors, making them suitable for specialized applications where precise monitoring is crucial.

- Niche Industries: Certain industries may require monitoring for specific gases due to their unique processes or environmental conditions. Single gas monitors cater to these niche applications.

5. Backup or Supplementary Monitoring:

- Redundancy: Single gas monitors can serve as backup devices in situations where primary multi-gas detectors are unavailable or undergoing maintenance.

- Supplementary Monitoring: In environments where the presence of a particular gas is of particular concern, users may opt to use single gas monitors in addition to multi-gas detectors for enhanced monitoring coverage.

6. Portability and Convenience:

- Compact Design: Single gas monitors are often more compact and lightweight compared to multi-gas detectors, making them easy to carry and use in various work settings, including confined spaces.

- Integration with Personal Protective Equipment (PPE): Some single gas monitors are designed to be integrated with personal protective equipment such as gas masks or respirators, providing real-time monitoring of gas levels directly to the wearer.

7. Regulatory Compliance:

- Specific Requirements: Certain regulations or industry standards may specify the use of single gas monitors for monitoring specific gases in particular work environments to ensure compliance with safety guidelines.

In summary, people use single gas monitors for their simplicity, cost-effectiveness, specialized functionality, and suitability for specific gas monitoring needs in various trades and industries. While they may not offer the comprehensive monitoring capabilities of multi-gas detectors, single gas monitors play a valuable role in enhancing workplace safety and mitigating the risks associated with hazardous gases.